Preventive Maintenance: A Guide

Preventive maintenance refers to regular, planned actions taken to keep equipment and systems in good working condition. These activities help prevent unexpected breakdowns and reduce the risk of costly downtime. It involves a variety of tasks such as inspections, lubrication, cleaning, and adjustments. Beyond manual upkeep, it also includes planning, scheduling, and documenting past maintenance records. This structured approach ensures that machinery remains reliable and efficient over time. Industries like manufacturing, oil and gas, mining, and utilities often rely heavily on preventive maintenance to ensure smooth operations. By implementing these practices, companies can avoid expensive repairs, extend equipment life, and maintain a safer work environment. Preventive maintenance is a proactive strategy that involves performing routine checks and maintenance at scheduled intervals. The goal is to identify and address potential issues before they escalate into major failures. This includes things like replacing worn parts, checking for leaks, and ensuring proper functioning of critical components. The main objective of preventive maintenance is to maintain the intended performance of equipment, reduce the risk of accidents, and minimize unplanned downtime. It also helps organizations comply with industry regulations and improve overall operational efficiency. Implementing a preventive maintenance program offers numerous benefits. It reduces the likelihood of equipment failure, lowers repair costs, and improves workplace safety. Companies that prioritize this approach often experience fewer disruptions in production and better long-term asset performance. Compared to reactive maintenance, which only addresses problems after they occur, preventive maintenance is more cost-effective and less disruptive. Reactive strategies can lead to extended downtime, higher repair bills, and even safety hazards. By staying ahead of potential issues, businesses can maintain consistent productivity and avoid the stress of sudden equipment failures. It’s a strategic investment that pays off over time through improved reliability and reduced operational risks. Preventive maintenance is a powerful tool for maintaining equipment and reducing operational risks. Here are some of its key benefits: Regular maintenance helps ensure that equipment runs smoothly and reliably. This minimizes the chance of unplanned downtime, which can be extremely costly. According to research, unplanned downtime can cost companies an average of $260,000 per hour in lost revenue. By keeping equipment in optimal condition, businesses can avoid disruptions and maintain steady production levels. This not only saves money but also protects customer relationships and company reputation. Proper maintenance extends the life of equipment by preventing wear and tear. Regular inspections and servicing allow companies to get the most out of their assets, delaying the need for costly replacements. This approach also reduces waste and supports sustainability efforts. When equipment lasts longer, it contributes to a more efficient and environmentally friendly operation. An inspector recording the operation of oil and gas process Well-maintained equipment is less likely to malfunction or fail unexpectedly, which significantly reduces the risk of workplace injuries. This creates a safer environment for employees and reduces liability for the company. Additionally, preventive maintenance reduces the need for emergency repairs, which can expose workers to dangerous conditions. By following a structured maintenance schedule, companies can protect their workforce and lower insurance and compensation costs. Many industries have strict regulations regarding equipment maintenance. Failing to meet these standards can result in fines, legal issues, or even shutdowns. Preventive maintenance ensures that all equipment is properly maintained and meets required safety and performance criteria. While preventive maintenance is highly effective, it is not without challenges. Some limitations include: Even with the best preventive maintenance plans, equipment failure cannot always be avoided. Unpredictable events such as natural disasters or human error can still cause issues. Therefore, it's important to combine preventive maintenance with other strategies like predictive maintenance for maximum effectiveness. Some older equipment may not have the sensors or monitoring capabilities needed for advanced maintenance techniques. In such cases, traditional methods must be used, which may not be as efficient as modern solutions. Implementing a preventive maintenance program requires an initial investment in training, tools, and time. For smaller businesses, this can be a challenge, especially if budgets are tight. However, the long-term savings usually outweigh the upfront costs. Performing preventive maintenance often requires shutting down equipment, which can affect production schedules. It can also be difficult to find enough time and resources to complete all necessary tasks, especially in busy environments. Effective preventive maintenance often requires additional staff or extended hours for existing workers. This can be a challenge in companies with limited resources or labor shortages. Sometimes, maintenance tasks are performed unnecessarily, leading to wasted time and money. A well-designed preventive maintenance plan should be flexible and based on historical data to avoid unnecessary interventions. There are three primary types of preventive maintenance: Time-based maintenance involves performing tasks at regular intervals, such as monthly, quarterly, or annually. This type is common for equipment that follows manufacturer guidelines. For example, changing an air filter every three months is a typical time-based task. However, this approach can sometimes lead to over-maintenance if the equipment isn’t used frequently. Usage-based maintenance is triggered by how much equipment is used. Instead of relying on time, this approach uses metrics like operating hours, miles driven, or cycle counts to determine when maintenance is needed. This method is particularly useful for equipment that is used irregularly, as it avoids unnecessary maintenance on underused assets. Condition-based maintenance focuses on the actual condition of equipment. Inspectors monitor factors like sound, temperature, vibration, and visual signs of wear to decide when maintenance is required. This approach allows for more targeted and efficient maintenance, as it only intervenes when necessary, rather than on a fixed schedule. Each type of preventive maintenance includes various tasks, which can be categorized based on priority and importance: A preventive maintenance checklist is a detailed list of tasks that should be performed regularly. It helps ensure that all necessary steps are followed, improving efficiency and reducing the risk of oversight. These checklists are often developed in collaboration with maintenance managers, workers, and regulatory bodies. Many companies use software to track and document their maintenance activities effectively. Using a checklist enhances consistency, reduces errors, and improves safety. It also streamlines planning and makes inspections faster and more accurate. Checklists vary by industry, but they typically cover essential tasks. Here are examples for different sectors: Drones are revolutionizing the way preventive maintenance is conducted. They offer a fast, safe, and efficient way to inspect hard-to-reach areas without disrupting operations. Equipped with advanced sensors and cameras, drones can perform visual inspections, collect data, and even assist in condition-based maintenance. This technology is especially valuable in hazardous environments where human access is limited. In one case study, the Elios 3 drone was used by the City of Lausanne’s Water Department to inspect infrastructure. Its LiDAR sensor created real-time maps, helping to track wear and tear and plan future maintenance efficiently. Drones not only reduce costs and time but also enhance worker safety by eliminating the need to enter dangerous spaces. As technology continues to evolve, the role of drones in preventive maintenance will only grow. Sheet Metal Fabrication,Precision Sheet Metal Fabrication,High Precision Turning Parts,High Precision Turning Parts Processing Shenzhen Yuheng Precision Machinery Co., Ltd. , https://www.yhcncmachiningparts.comPreventive Maintenance: A Comprehensive Guide

What Is Preventive Maintenance?

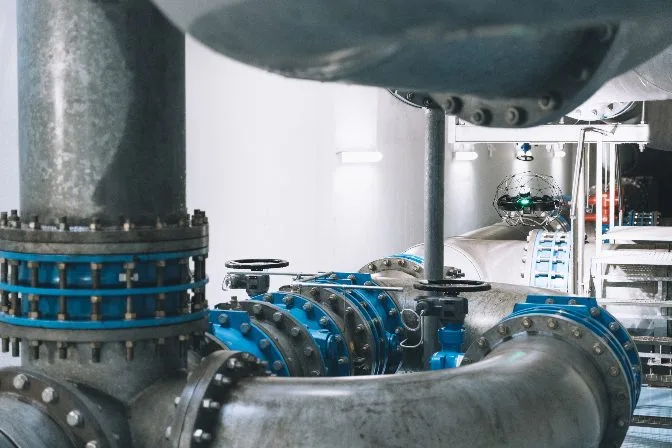

The Elios 3 inspecting a water management system

The Elios 3 inspecting a water management systemWhy Is Preventive Maintenance Important?

Advantages of Preventive Maintenance

Minimizes Downtime

Maximizes Equipment Lifespan

Helps Keep Workers Safe

Helps Ensure Regulatory Compliance

Limitations of Preventive Maintenance

Success Rate

Technological Constraints

Up Front Costs

Time Constraints

Worker Limitations

Over Maintenance

What Are the Types of Preventive Maintenance?

Time-Based Maintenance

Cleaning a condenser tube from a chiller

Cleaning a condenser tube from a chillerUsage-Based Maintenance

Condition-Based Maintenance

Types of Preventive Maintenance Tasks

What is a Preventive Maintenance Checklist?

Benefits of a Preventive Maintenance Checklist

Preventive Maintenance Checklist Examples

Building Interior Preventive Maintenance Checklist

Network and Data Systems Preventive Maintenance Checklist

Semi Truck Preventive Maintenance Checklist

Drones in Preventive Maintenance

An Elios 3 drone performing a visual inspection

An Elios 3 drone performing a visual inspection