Mining Tools in 2022—A Guide to Mining Equipment and Mining Machines

The term "mining tools" refers broadly to all the equipment and machines used in the extraction of minerals from the earth. These tools are essential for accessing and processing a wide range of resources that support modern life, from energy production to consumer goods. This guide explores the different types of mining methods, the tools used in each, and the role of modern technology in enhancing safety and efficiency in the industry. Before diving into specific tools, it's important to understand the various mining techniques. The approach taken depends on the type of mineral being extracted and its location—whether it’s near the surface or deep underground. With this foundation, we’ll break down the main mining methods and the specialized equipment used in each, giving you a comprehensive overview of the tools that power the mining industry. Mining can be categorized into four main types: underground, open-pit (surface), placer, and in-situ. Each method involves different tools and processes depending on the nature of the resource and the environment in which it’s found. Despite the differences, most mining operations follow a similar sequence of steps: Surface mining is used when minerals are close to the earth’s surface. Common techniques include: When minerals are too deep for surface methods, underground mining is used. Techniques vary based on the geology and accessibility of the deposit: Soft and hard rock mining require different approaches and tools. Soft rocks like salt and coal don’t need explosives, while hard rocks such as copper and gold often do. Hard rock mining typically uses hydraulic drills to create holes for explosives, whereas soft rock mining relies on mechanical excavation. This distinction shapes the choice of machinery and safety protocols in each setting. The mining industry uses a vast array of tools, from basic hand tools to advanced machinery. These tools are tailored to the specific needs of each mining method and environment. Instead of listing every tool, we’ve organized them by category, covering everything from personal protective equipment (PPE) to large-scale machinery used in both surface and underground mining. Here’s an overview of the main categories: Personal protective equipment is crucial for miner safety. Key items include: Surface mining relies on heavy machinery to move and process large volumes of material. Key tools include: Underground mining requires compact, durable tools designed for confined spaces. Examples include: Many underground machines are emission-free and built to handle extreme conditions, ensuring both safety and efficiency in challenging environments. Additional tools used in both surface and underground mining include hoppers, conveyors, crushers, and mills. These play a critical role in transporting, processing, and refining raw materials. Modern mining also benefits from digital tools like LiDAR and drones, which improve surveying, documentation, and inspection. As the industry evolves, new technologies are becoming increasingly vital to improving safety, efficiency, and sustainability. Mining Tools: rugged and ready for hard work The mining industry has been around for thousands of years, and even today, it demands robust equipment that can withstand harsh conditions. With the rise of digitalization, tools like LiDAR and drones are now helping to transform traditional practices, making mining safer and more efficient than ever before. Diamond Wire Loop,Diamond Wire Saw Rope,Diamond Wire Ring,Diamond Cutting Lines Changzhou Kuaile Technology Co., Ltd , https://www.quartzglasssectionmachine.comMining Tools — A Guide to Mining Equipment and Machines

Types of Mining Methods

Surface Mining Methods

Open-pit mine | Source: Adam Rhodes on Unsplash

Open-pit mine | Source: Adam Rhodes on UnsplashUnderground Mining Methods

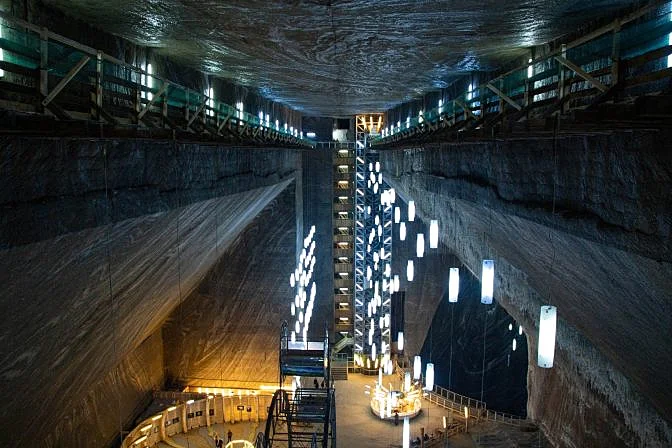

Salt mine | Source: Szabolcs Molnar from Pixabay

Salt mine | Source: Szabolcs Molnar from PixabayMining Equipment for Soft vs. Hard Rock Mines

Mining Tools and Equipment

Mining PPE

Surface Mining Equipment

Blasthole drill | Source: Cat Models

Blasthole drill | Source: Cat ModelsUnderground Mining Equipment

Elios 3 drone | Source: Flyability

Elios 3 drone | Source: FlyabilityOther Mining Tools