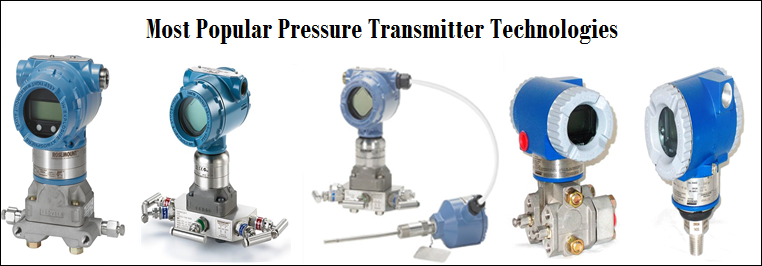

Pressure transmitters are essential components in the global process industries, tasked with measuring the pressure of gases and liquids used in these sectors. As critical tools, their underlying technologies have become increasingly significant. Initially relying on capacitance and piezo-resistive technologies, modern pressure transmitters now leverage advanced microprocessor-based systems. These sophisticated devices are often referred to as "smart transmitters," thanks to their ability to enable remote and bi-directional communication while offering temperature and pressure compensation. Today, several popular smart pressure transmitter technologies dominate the market. Curious about what they are? This post explores some of the top choices.

### Top 5 Prominent Pressure Measurement Technologies

1. **Wireless Pressure Transmitters**: Wireless pressure transmitters are gaining traction in hard-to-reach areas due to their convenience and cost-effectiveness during installation. Utilizing ultrasonic signals for communication, these transmitters ensure secure data transmission. Battery-powered models are particularly useful in remote locations where there’s no access to power lines. Among the most popular is the 3051c model, which excels in abusive environments while simplifying installation processes.

2. **Mass Flow or Multivariable Transmitters**: Also called multivariable transmitters, these instruments consolidate temperature, differential pressure, and gauge pressure measurements into a single flow computer unit. This integration reduces the need for standalone flow computers, streamlining operations and saving costs. They’re widely used for precise mass flow measurements, making them indispensable in many industrial setups.

3. **Smart Line Multivariable Transmitters with Integrated Primary Variables**: Combining advanced microprocessor technologies, these transmitters integrate sensors with dynamic flow compensation to deliver highly accurate flow measurements. They can account for complex variables like thermal expansion, viscosity, and discharge coefficients. The IGP10 and IDP10 models stand out for their dual capability of measuring absolute pressure and transmitting signals in both analog and digital formats.

4. **Multi-Sensing Transmitters**: Increasingly vital in demanding applications, multi-sensing transmitters offer unparalleled precision and reliability. They transmit multiple process readings—such as flow rates—to external units like flow computers or RTUs. For example, Yokogawa’s EJX-A series, particularly the EJX930A, leverages the unique features of its DPharp sensor for superior visibility and performance in challenging conditions.

5. **Coplanar Pressure Transmitters**: Designed to measure absolute and gauge pressures, coplanar transmitters boast user-friendly menus and flexible installation options. They are ideal for integrated pressure solutions. The 3051s is a prime example, ensuring precise measurements of gauge and differential pressures while maintaining operational ease.

In conclusion, these popular trends are reshaping the pressure transmitter industry. If you're looking to capitalize on these advancements, consider reaching out to a trusted supplier. The Transmitter Shop remains a standout provider, offering a diverse selection of pressure transmitters from leading brands in various configurations.

---

**Related Posts**

- What Are the Steps Involved in Calibrating Pressure Gauges?

- All Important Questions on Reconditioned Transmitters Answered

- Is a Remanufactured Transmitter a Better Option Than a New One?

- Differential Pressure Transmitters: How Do They Aid in Flow Measurements?

- 3 Whys That Explain How Often You Should Calibrate Pressure Transducers

- Guidelines for Troubleshooting Pressure Transducers

- Learn How to Calibrate a Pressure Transmitter – II

- Learn How to Calibrate a Pressure Transmitter

- Know Three Interesting Uses of Pressure Transmitters

- The Features and Benefits of Rosemount 1199 Direct Mount Transmitters

- 3 Major Pressure Transmitter Technologies That Made the Device Popular

- An Unconventional Guide to Selecting the Right Pressure Sensor

- Factors To Be Considered While Differentiating $40 and $400 Pressure Transmitters

- Tips to Augment the Performance and Service Life of Pressure Transmitters

- Factors of Consideration When Choosing Pressure Transmitter Manifolds

- Safety Tips for Differential Pressure Transmitter Operation

- Impact of Shock and Vibration on Pressure Transducers

- Rosemount 3051S vs 3051C Transmitter – What Is Your Choice?

- Rosemount 2088 Vs Rosemount 3051 – A Few Points of Differences Discussed

- What Are Diaphragm Seals and Their Types?

- Difference in Conventional Transmitters and Smart Transmitters

- How to Choose Diaphragm Seals for Your Application?

- How to Select Pressure Transmitters for Your Application?

- Remote Seals: Significance, Working Principle & Applications

- How Do You Calibrate A Flow Transmitter?

- What is Absolute Pressure Transmitter & How Does It Work?

- HART Communication Protocol: Overview, Working Principle, Benefits in Industrial Automation

- Absolute and Gauge Pressure Transmitters - Overview and Working Principle

- Flow Meter vs Flow Transmitter: Know the Difference

- Temperature Transmitter: How to Select The Efficient One for Your Application?

- How Do You Test for 4 to 20mA Signal in a Pressure Transmitter?

- Multivariable Transmitter: What Is It and How Does It Work?

- Pressure Transmitters vs. Pressure Transducers: Learn the Differential Characteristics

- Procedure to Calculate Accuracy of Pressure Transmitter Discussed

- An Ultimate Selection Guide for Flow Transmitters

- The Benefits and Challenges of HVAC System Balancing

- Understanding Pressure Ranges and Units for Fluid System Monitoring

- Understanding the Impact of Pressure Fluctuations on Drying Performance

- Monitoring and Controlling Energy Production in Power Plants

- Common Challenges in Air Flow Measurement and How to Overcome Them

- Pressure Monitoring in Pump Systems: A Comprehensive Guide

- Exploring Density and Viscosity Measurement in Industrial Processes

Track Undercarriage

Track Undercarriage,Steel Tracks For Mini Excavator,Excavator Track Chains,Skid Steer Track Chains

Ningbo Beilun Mingrui Hydraulic Equipment Co., Ltd , https://www.track-chassis.com