# Tips for Warehouse Fire Safety

As the number of fire incidents continues to rise, ensuring warehouse fire safety has never been more important. Warehouse fires can be triggered by various factors, including faulty electrical systems, malfunctioning machinery, and human errors. Therefore, it's essential for warehouse owners and managers to adopt proactive measures to prevent these disasters. By implementing regular maintenance, conducting thorough inspections, and offering comprehensive training to staff, businesses can greatly reduce the risk of fire.

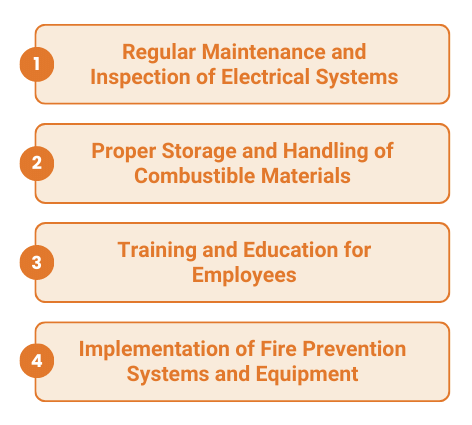

## Four Key Strategies for Effective Fire Prevention

Fire prevention requires a multi-faceted approach involving routine upkeep, employee education, and the installation of fire prevention systems and tools.

Adopting these preventive measures can significantly lower the chances of a fire breaking out in your warehouse:

### 1. Regular Maintenance and Inspection of Electrical Systems

Faulty electrical systems are a frequent cause of warehouse fires. To avoid such incidents, it's vital to schedule consistent maintenance and inspections of all electrical components within your warehouse. This includes checking electrical panels, wiring, and any devices used in daily operations.

### 2. Safe Storage and Handling of Flammable Materials

Materials like cardboard boxes, wooden pallets, and paper products, commonly found in warehouses, are highly combustible. Ensure these materials are stored in designated areas away from potential ignition sources like electrical equipment. This helps mitigate the risk of fire. Also, stack materials securely to prevent tipping or collapse, which can pose additional fire hazards.

### 3. Employee Training and Education

Educating your workforce about fire safety is critical for preventing warehouse fires. Make sure all employees are trained in the proper handling and storage of flammable materials, as well as basic fire prevention techniques. Additionally, ensure employees know how to operate fire extinguishers and other fire suppression equipment in emergencies.

### 4. Installation of Fire Prevention Systems and Equipment

Implementing fire prevention systems and equipment can further reduce the risk of fire. Consider installing smoke detectors, fire alarms, sprinkler systems, and fire suppression gear.

## Ensuring Safety During Emergencies

An emergency response plan is a vital part of any warehouse safety program. In the face of an emergency, having a clear plan can ensure the safety of employees and minimize property damage. A well-prepared plan allows employees to respond swiftly and efficiently, ensuring everyone is accounted for and safely evacuated.

An effective emergency response plan should outline the roles and responsibilities of all employees during emergencies. Designate leaders who will oversee the response and ensure accountability.

The plan should also specify emergency exit routes and procedures. Include floor plans and designated assembly areas. Ensure these routes and procedures are clearly marked and adequately lit.

Communication is key during emergencies. Incorporate a communication strategy that keeps everyone informed. This could involve using a public address system, sending emergency broadcasts, or employing other communication methods.

Lastly, regularly review and update the emergency response plan as needed. Train all employees on the plan and conduct regular drills to identify potential issues and areas for improvement.

By having a robust emergency response plan in place, warehouse managers can safeguard their employees and limit property damage during emergencies.

Learn more about how a fire prevention plan can enhance your workplace safety.

## Protect Your Warehouse with MoviTHERM’s Innovative Solutions

Preventing warehouse fires is crucial for safeguarding employees, assets, and businesses. MoviTHERM offers cutting-edge solutions to help warehouse managers stay ahead in fire prevention. One of these solutions involves using thermal imaging cameras for early fire detection.

Thermal cameras can detect temperature changes, even in areas where conventional smoke detectors might fail. Early detection provides valuable time for intervention, preventing minor issues from escalating into major catastrophes.

In addition to early fire detection, MoviTHERM’s condition monitoring solutions can assess the health of your equipment to prevent failures. By monitoring equipment temperatures, potential problems can be identified and resolved before they lead to fires. MoviTHERM’s system sends real-time alerts for overheating or abnormal temperature changes, giving managers the chance to act before a fire starts.

Overall, MoviTHERM’s early fire detection and condition monitoring solutions offer a proactive approach to warehouse fire prevention. By identifying issues early and providing instant alerts, warehouse managers can take preemptive action to stop fires before they begin. With MoviTHERM’s solutions, managers can protect their employees, assets, and businesses.

---

*Note: Thank you for signing up! You'll receive updates shortly.*

---

### Explore Our Products

All Products

Bundles

IR Cameras

Enclosures

Pan-Tilt Units

Accessories

I/O Modules

irNDT Systems

Blackbody Sources

IoT Monitoring Kits

tools for radiator repair

Guangzhou Casselin Trading Co., Ltd. , https://www.casselinautoparts.com