Carbon steel seamless pipe are stronger and durable due to seamless structure which gives potential at fault point. It has standard shape and design which gives consistent mechanical feature for the whole length of pipe. It even gives better resistance at higher temperature due to no joints.

It gives higher accurateness in terms of sizes and thickness which gives more predictable performances in several environments.

Carbon steel welded pipe has less strength and durability as compared to seamless pipe. It is primarily due to the welding process itself. The heat affected area near the weld can come across changes in microstructure and mechanical properties, which may lead to low toughness and resistance to exhaust.

It can leave weld beads and heat affected area patch on its surface, which will need more treatment or cleaning process to meet the desired requirement.

Seamless carbon steel pipe is utilize as follows:

High pressure applications

It is usually preferred for high pressure application, such as in oil and gas industry for moving liquids at higher pressure as there will be no risk of leakages.

Hydraulic System

It is appropriate for this application as it has the potential to hold high pressure and it even has smooth interior surface which decreases adhesion loss.

Critical liquid transport

It is used for critical applications where strength of the pipe is essential, such as in chemical processing, nuclear plants, and power generation industry.

Welded carbon steel pipe is utilize as follows:

Medium pressure and temperature

It is appropriate where medium pressure and temperature are demanded such as low-pressure steam systems.

Non-corrosive Fluids

It is appropriate for moving non-corrosive fluids where there is no risk or minimum risk of corrosion such as for distributing water.

Manufacturing Process

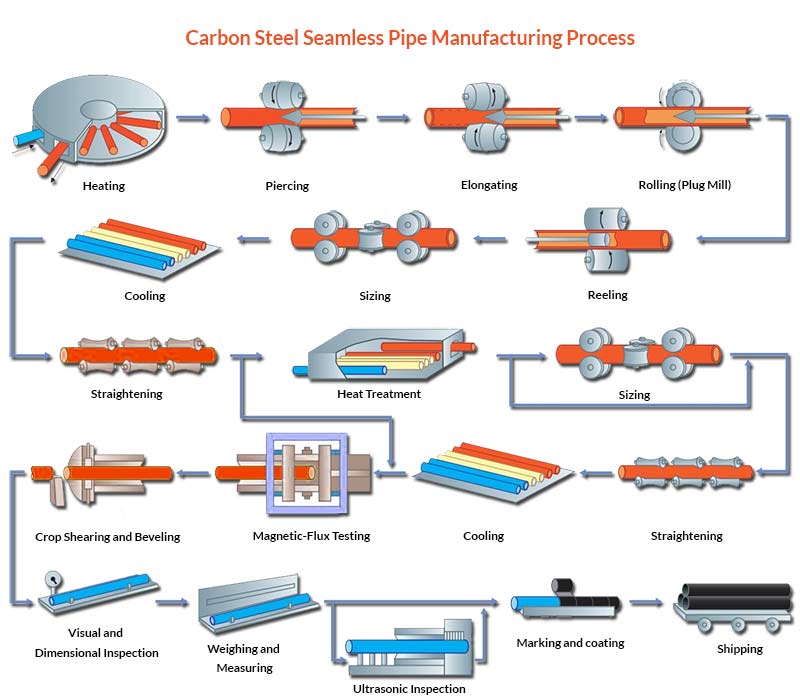

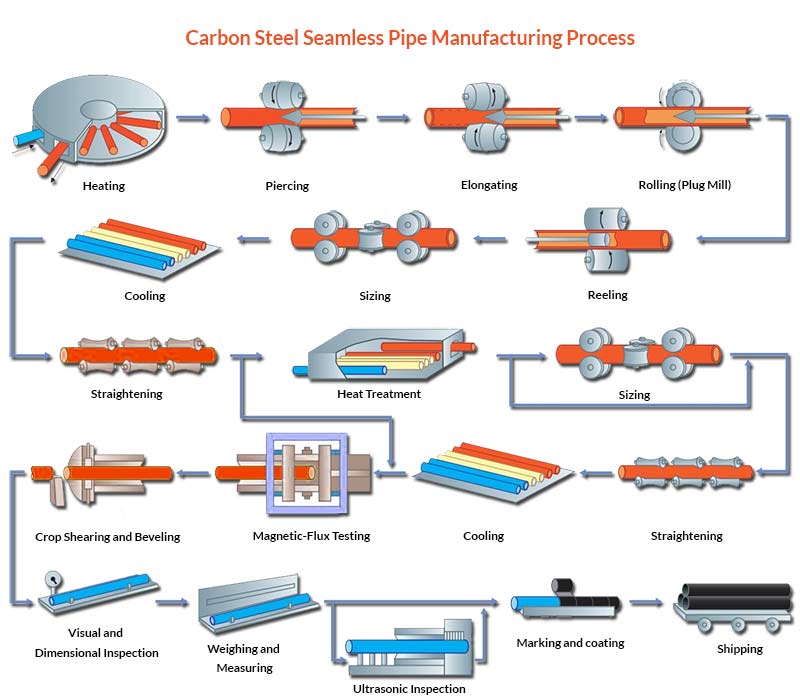

Seamless carbon pipe are manufactured by extruding a solid steel bar in order to make a hollow pipe. It has no joints or welding, that means it has a standard design.

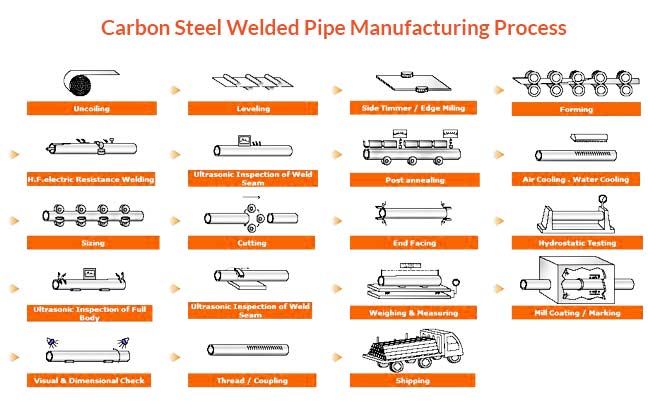

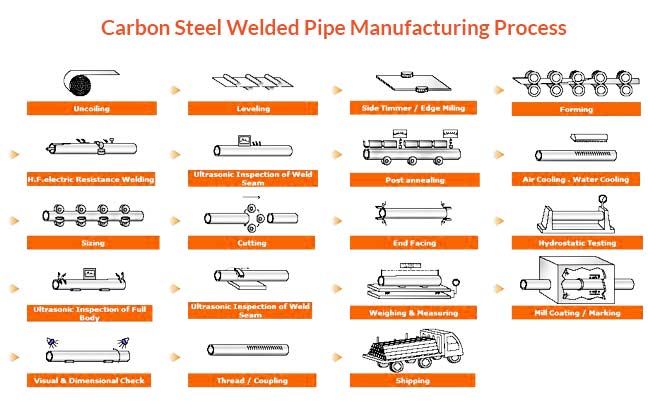

Welded carbon pipe are manufactured by rolling a flat plate and formed into a cylindrical shape and then it is been welded. It is commonly welded by longitudinally welded (LSAW) and spiral welded (SSAW).

Why to select?

Carbon seamless pipe gives superior strength, reliability at higher pressure conditions in essential applications where strength is most essential.

Carbon welded pipe is cost effective, easy to manufacture, and suitable for medium pressure and temperature applications.

Table of contents

- Carbon Steel seamless and welded pipe manufacturing process

- Seamless vs Welded Carbon Steel Pipe Specification

- Carbon steel Welded and seamless pipe equivalent

- Tolerances for hot finished seamless pipe

- Tolerances for cold drawn welded tubes

- Carbon Steel seamless and welded pipes chemical composition

- CS Welded and Seam Pipe mechanical properties

- List of documents to import Low Temp Welded Pipe

- A106 Seamless and Welded Pipe Schedule

- CS Welded and Seamless Pipe International Standard

- Hot finished welded type tubes sizes in mm

- Difference between seamless pipe and erw pipe

- Maximum Allowed Stress of DIN EN 10220 seamless steel pipes

- Low Temp Seamless Pipe Charpy V-Notch Impact Tests

- Hot Forming and Heat Treatment of CS ERW and Seamless pipe

- List of machinery to produce seamless pipe

- List of machinery to produce welded pipe

- Testing for Seam pipe and ERW Pipe

List of Seamless Carbon Steel Pipe grades for high-temperature service, check uses and manufacturing process of CS SMLS and Welded pipes

Carbon Steel seamless and welded pipe manufacturing process

Carbon steel seamless pipe manufacturing process

Carbon steel welded pipe manufacturing process

Check Carbon Steel welded and seamless pipe specifications, equivalent, tolerances, and properties

Seamless vs Welded Carbon Steel Pipe Specification

Carbon steel Welded and seamless pipe equivalent

| DIN |

BS |

NFA |

ASTM |

| DIN 17175 Grade 17 Mn 4 |

NFAA 49-213 Grade TU 48-c |

ASTM A106 Grade C |

ASME SA 106 Grade C |

Tolerances for hot finished seamless pipe

Outside Diameter Range

(inches) |

Wall Percent

of O.D. |

Unannealed or Stress

Relief Annealed |

Oil Quenched &

Tempered |

Soft Annealed or

Normalized |

| O.D. Inches |

I.D. Inches |

O.D. & I.D. |

O.D. Inches |

I.D. Inches |

| Plus |

Minus |

Plus |

Minus |

Plus/Minus |

Plus |

Minus |

Plus |

Minus |

| Up to 0.499 |

All |

0.004 |

0.000 |

|

|

0.005 |

0.005 |

0.002 |

|

|

| 0.500-1.699 |

All |

0.005 |

0.000 |

0.000 |

0.005 |

0.005 |

0.007 |

0.002 |

0.002 |

0.007 |

| 1.700-2.099 |

All |

0.006 |

0.000 |

0.000 |

0.006 |

0.008 |

0.006 |

0.005 |

0.005 |

0.006 |

| 2.100-2.499 |

|

0.007 |

0.000 |

0.000 |

0.007 |

0.009 |

0.008 |

0.005 |

0.005 |

0.008 |

| 2.500-2.899 |

All |

0.008 |

0.000 |

0.000 |

0.008 |

0.010 |

0.009 |

0.005 |

0.005 |

0.009 |

| 2.900-3.299 |

All |

0.009 |

0.000 |

0.000 |

0.009 |

0.012 |

0.011 |

0.005 |

0.005 |

0.011 |

| 3.300-3.699 |

All |

0.010 |

0.000 |

0.000 |

0.010 |

0.013 |

0.013 |

0.005 |

0.005 |

0.013 |

| 3.700-4.099 |

All |

0.011 |

0.000 |

0.000 |

0.011 |

0.014 |

0.013 |

0.007 |

0.010 |

0.010 |

| 4.100-4.499 |

All |

0.012 |

0.000 |

0.000 |

0.012 |

0.015 |

0.014 |

0.007 |

0.011 |

0.011 |

| 4.500-4.899 |

All |

0.013 |

0.000 |

0.000 |

0.013 |

0.017 |

0.016 |

0.007 |

0.012 |

0.012 |

| 4.900-5.299 |

All |

0.014 |

0.000 |

0.000 |

0.014 |

0.018 |

0.018 |

0.007 |

0.013 |

0.013 |

| 5.300-5.549 |

All |

0.015 |

0.000 |

0.000 |

0.015 |

0.019 |

0.020 |

0.007 |

0.014 |

0.014 |

| 5.550-5.999 |

Under 6 |

0.010 |

0.010 |

0.010 |

0.010 |

0.025 |

0.018 |

0.018 |

0.018 |

0.018 |

| 6 to 7 1/2 |

0.009 |

0.009 |

0.009 |

0.009 |

0.023 |

0.016 |

0.016 |

0.016 |

0.016 |

| Over 7 1/2 |

0.018 |

0.000 |

0.009 |

0.009 |

0.023 |

0.017 |

0.015 |

0.016 |

0.016 |

Tolerances for cold drawn welded tubes

Size Range

Inch (mm) |

OD Tolerance Inch (mm) |

| Over |

Under |

| Up to 2.999 (76.17) |

0.020 (0.51) |

0.020 (0.51) |

| 3.000-4.499 (76.20-114.27) |

0.025 (0.64) |

0.025 (0.64) |

| 4.500-5.999 (114.30-152.37) |

0.031 (0.79) |

0.031 (0.79) |

| 6.000-7.499 (152.40-190.47) |

0.037 (0.94) |

0.037 (0.94) |

| 7.500-8.999 (190.50-228.57) |

0.045 (1.14) |

0.045 (1.14) |

| 9.000-10.750 (228.60-273.05) |

0.050 (1.27) |

0.050 (1.27) |

| 10.750 and larger |

1% |

1% |

Carbon Steel seamless and welded pipes chemical composition

ASTM A53

| Values in % |

Type S

(Seamless) |

Type F

(Furnace Weld) |

Type E

(ERW) |

| A53 |

Grade A |

Grade B |

Grade A |

Grade A |

Grade B |

| Manganese |

0.95 |

1.2 |

1.2 |

0.95 |

1.2 |

| Carbon |

0.25 |

0.3 |

0.3 |

0.25 |

0.3 |

| Sulfur |

0.045 |

0.045 |

0.045 |

0.045 |

0.045 |

| Phosphorous |

0.05 |

0.05 |

0.05 |

0.05 |

0.05 |

| Nickel |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

| Copper |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

| Molybdenum |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

| Chromium |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

| Vanadium |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

ASTM A106

| Element |

Mn |

C

max |

S

max |

P

max |

Cr

max (3) |

Si

min |

Mo

max (3) |

Cu

max (3) |

V

max (3) |

Ni

max (3) |

| Grade A |

0.27-0.93 |

0.25 (1) |

0.035 |

0.035 |

0.40 |

0.10 |

0.15 |

0.40 |

0.08 |

0.40 |

| Grade B |

0.29-1.06 |

0.30 (2) |

0.035 |

0.035 |

0.40 |

0.10 |

0.15 |

0.40 |

0.08 |

0.40 |

| Grade C |

0.29-1.06 |

0.35 (2) |

0.035 |

0.035 |

0.40 |

0.10 |

0.15 |

0.40 |

0.08 |

0.40 |

ASTM A333

| Element |

Grade 3 |

Grade 6 |

| C |

0.19 |

0.30 |

| Mn |

0.31–0.64 |

0.29–1.06 |

| P |

0.025 |

0.025 |

| S |

0.025 |

0.025 |

| Si |

0.18–0.37 |

0.10 min |

| Ni |

3.18–3.82 |

0.40 |

| Cr |

… |

0.30 |

| Cu |

… |

0.40 |

| Al |

… |

… |

| V |

… |

0.08 |

| Cb |

… |

0.02 |

| Mo |

… |

0.12 |

| Co |

… |

… |

CS Welded and Seam Pipe mechanical properties

ASTM A53

| Seamless and ERW |

A53 Grade B |

A53 Grade A |

| Yield Strength |

35,000 |

30,000 |

| Tensile Strength, min, psi |

60,000 |

48,000 |

ASTM A106

| ASTM A106 |

Grade A |

Grade B |

Grade C |

| Yield Strength, min., psi |

30,000 |

35,000 |

40,000 |

| Tensile Strength, min., psi |

48,000 |

60,000 |

70,000 |

ASTM A333

| ASTM A333 |

Yield Strength, min. |

Tensile Strength, min. |

Elongation %, min. |

| Grade |

psi |

MPa |

psi |

MPa |

Longitudinal |

Transverse |

| Grade 3 |

35 000 |

240 |

65 000 |

450 |

30 |

20 |

| Grade 6 |

35 000 |

240 |

60 000 |

415 |

30 |

16.5 |

List of documents to import Carbon Steel Seamless Pipe, check MTC sample for Seamless vs Welded CS Pipe

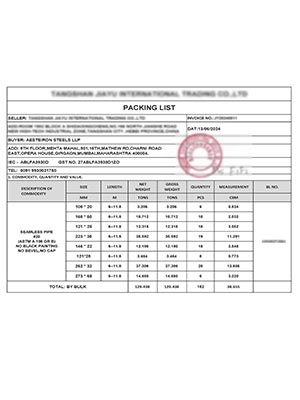

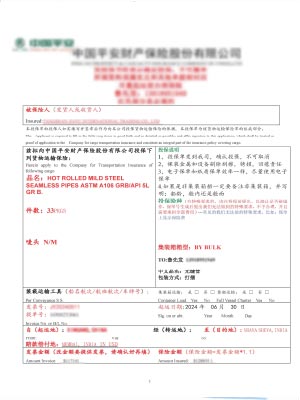

List of documents to import Low Temp Welded Pipe

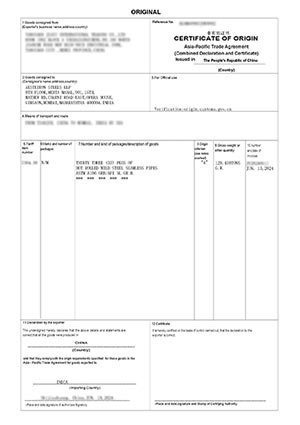

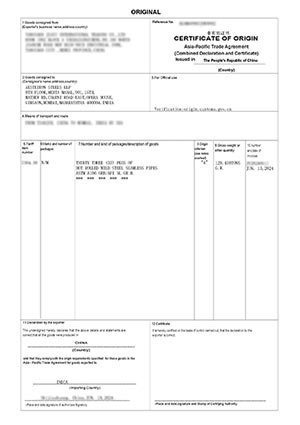

Certificate of Origin

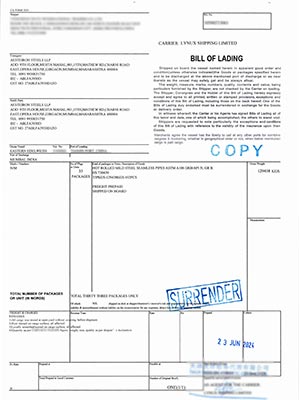

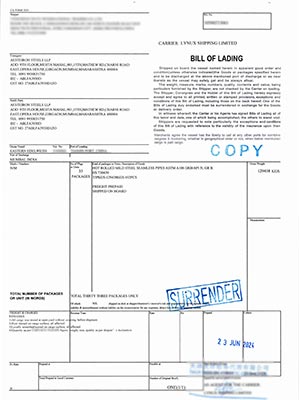

Bill of Lading

Commercial Invoice

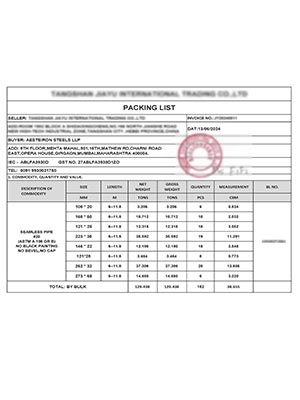

Packing list

Material Test Certificate

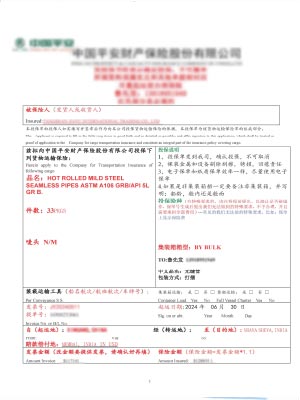

Insurance Certificate

Refer Weight Chart, Schedule, International Standard, and sizes in mm for Welded and Seamless Carbon Steel Pipe

A106 Seamless and Welded Pipe Schedule

| NPS |

Outside Diameter |

Inside Diameter |

Schedules |

| 1/8″ |

.405 |

.307 |

10, 10S |

| .269 |

40, STD, 40S |

| .215 |

80, XS, 80S |

| 1/4″ |

.540 |

.410 |

10, 10S |

| .364 |

40, STD, 40S |

| .302 |

80, XS, 80S |

| 3/8″ |

.675 |

.545 |

10, 10S |

| .493 |

40, STD, 40S |

| .423 |

80, XS, 80S |

| 1/2″ |

.840 |

.674 |

10, 10S |

| .622 |

40, STD, 40S |

| .546 |

80, XS, 80S |

| .466 |

160 |

| .252 |

XX |

| 3/4″ |

1.050 |

.884 |

10, 10S |

| .824 |

40, STD, 40S |

| .742 |

80, XS, 80S |

| .614 |

160 |

| .434 |

XX |

| 1″ |

1.315 |

1.097 |

10, 10S |

| 1.049 |

40, STD, 40S |

| .957 |

80, XS, 80S |

| .815 |

160 |

| .599 |

XX |

| 1 1/4″ |

1.660 |

1.442 |

10, 10S |

| 1.380 |

40, STD, 40S |

| 1.278 |

80, XS, 80S |

| 1.160 |

160 |

| .896 |

XX |

| 1 1/2″ |

1.900 |

1.682 |

10, 10S |

| 1.610 |

40, STD, 40S |

| 1.500 |

80, XS, 80S |

| 1.337 |

160 |

| 1.100 |

XX |

| 2″ |

2.375 |

2.157 |

10, 10S |

| 2.067 |

40, STD, 40S |

| 1.939 |

80, XS, 80S |

| 1.687 |

160 |

| 1.503 |

XX |

| 2 1/2″ |

2.875 |

2.635 |

10, 10S |

| 2.469 |

40, STD, 40S |

| 2.323 |

80, XS, 80S |

| 2.125 |

160 |

| 1.771 |

XX |

| 3″ |

3.500 |

3.260 |

10, 10S |

| 3.068 |

40, STD, 40S |

| 2.900 |

80, XS, 80S |

| 2.624 |

160 |

| 2.300 |

XX |

| 3 1/2″ |

4.000 |

3.760 |

10, 10S |

| 3.548 |

40, STD, 40S |

| 3.364 |

80, XS, 80S |

| 2.728 |

XX |

| 4″ |

4.500 |

4.260 |

10, 10S |

| 4.026 |

40, STD, 40S |

| 3.826 |

80, XS, 80S |

| 3.624 |

120 |

| 3.438 |

160 |

| 3.152 |

XX |

| 4 1/2″ |

5.000 |

4.506 |

STD, 40S |

| 4.290 |

XS, 80S |

| 5″ |

5.563 |

5.295 |

10, 10S |

| 5.047 |

40, STD, 40S |

| 4.813 |

80, XS, 80S |

| 4.563 |

120 |

| 4.313 |

160 |

| 4.063 |

XX |

| 6″ |

6.625 |

6.357 |

10, 10S |

| 6.065 |

40, STD, 40S |

| 5.761 |

80, XS, 80S |

| 5.501 |

120 |

| 5.189 |

160 |

| 4.897 |

XX |

| 8″ |

8.625 |

8.329 |

10, 10S |

| 8.125 |

20 |

| 8.071 |

30 |

| 7.981 |

40, STD, 40S |

| 7.813 |

60 |

| 7.625 |

80, XS, 80S |

| 7.439 |

100 |

| 7.189 |

120 |

| 7.001 |

140 |

| 6.813 |

160 |

| 6.875 |

XX |

| 10″ |

10.750 |

10.420 |

10, 10S |

| 10.250 |

20 |

| 10.136 |

30 |

| 10.020 |

40, STD, 40S |

| 9.750 |

60, XS, 80S |

| 9.564 |

80 |

| 9.314 |

100 |

| 9.064 |

120 |

| 8.750 |

140, XX |

| 8.500 |

160 |

| 12″ |

12.750 |

12.390 |

10, 10S |

| 12.250 |

20 |

| 12.090 |

30 |

| 12.000 |

STD, 40S |

| 11.938 |

40 |

| 11.750 |

XS, 80S |

| 11.626 |

60 |

| 11.376 |

80 |

| 11.064 |

100 |

| 10.750 |

120, XX |

| 10.500 |

140 |

| 10.126 |

160 |

| 14″ |

14.000 |

13.624 |

10S |

| 13.500 |

10 |

| 13.375 |

20 |

| 13.250 |

30, STD, 40S |

| 13.124 |

40 |

| 13.000 |

XS, 80S |

| 12.814 |

60 |

| 12.500 |

80 |

| 12.124 |

100 |

| 11.814 |

120 |

| 11.500 |

140 |

| 11.188 |

160 |

| 16″ |

16.000 |

15.624 |

10S |

| 15.500 |

10 |

| 15.375 |

20 |

| 15.250 |

30, STD, 40S |

| 15.000 |

40, XS, 80S |

| 14.688 |

60 |

| 14.314 |

80 |

| 13.938 |

100 |

| 13.564 |

120 |

| 13.124 |

140 |

| 12.814 |

160 |

| 18″ |

18.000 |

17.624 |

10S |

| 17.500 |

10 |

| 17.375 |

20 |

| 17.250 |

STD, 40S |

| 17.124 |

30 |

| 17.000 |

XS, 80S |

| 16.876 |

40 |

| 16.500 |

60 |

| 16.126 |

80 |

| 15.688 |

100 |

| 15.250 |

120 |

| 14.876 |

140 |

| 14.438 |

160 |

| 20″ |

20.000 |

19.564 |

10S |

| 19.500 |

10 |

| 19.250 |

20, STD, 40S |

| 19.000 |

30, XS, 80S |

| 18.812 |

40 |

| 18.376 |

60 |

| 17.938 |

80 |

| 17.438 |

100 |

| 17.000 |

120 |

| 16.500 |

140 |

| 16.064 |

160 |

| 24″ |

24.000 |

23.500 |

10, 10S |

| 23.250 |

20, STD, 40S |

| 23.000 |

XS, 80S |

| 22.876 |

30 |

| 22.626 |

40 |

| 22.064 |

60 |

| 21.564 |

80 |

| 20.938 |

100 |

| 20.376 |

120 |

| 19.876 |

140 |

| 19.314 |

160 |

| 30″ |

30.000 |

29.376 |

10, 10S |

| 29.250 |

STD, 40S |

| 29.000 |

20, XS, 80S |

| 28.750 |

30 |

| 36″ |

36.000 |

35.376 |

10 |

| 35.250 |

STD, 40S |

| 35.000 |

XS, 80S |

| 34.750 |

30 |

| 48″ |

48.000 |

47.250 |

STD, 40S |

| 47.000 |

XS, 80S |

CS Welded and Seamless Pipe International Standard

| Product Name |

Standard |

| Electric-Resistance-Welded Steel Pipes |

ASTM A135 |

| ERW and Hot-dip Galvanized Steel Pipes |

ASTM A53 |

| Pipes for Piling Usage |

ASTM A252 |

| Tubes for General Structural Purpose |

ASTM A500 |

| CS Tubes for General Structure Purpose |

JIS G3444 |

| Carbon Steel Tubes for Machine Structure Purpose |

JIS G3445 |

| CS Pipes for Ordinary Piping |

JIS G3452 |

| Carbon Steel Pipes for Pressure Service |

JIS G3454 |

| Carbon Steel Rectangular Pipes for General Structure |

JIS G3466 |

Hot finished welded type tubes sizes in mm

| Outside Diameter (MM) |

Wall Thickness (MM) |

BWG |

| 4.78 |

0.89 |

20 |

| 6.35 |

0.51 |

|

| 0.71 |

22 |

| 0.89 |

20 |

| 1.25 |

18 |

| 1.65 |

16 |

| 7.95 |

0.89 |

20 |

| 1.25 |

18 |

| 9.53 |

0.71 |

22 |

| 0.89 |

20 |

| 1.25 |

18 |

| 1.65 |

16 |

| 12.7 |

0.89 |

20 |

| 1.25 |

18 |

| 1.65 |

16 |

| 15.88 |

0.89 |

20 |

| 1.25 |

18 |

| 1.65 |

16 |

| 19.05 |

0.89 |

20 |

| 1.25 |

18 |

| 1.65 |

16 |

| 2.11 |

14 |

| 3.05 |

11 |

| 22.23 |

0.89 |

20 |

| 1.25 |

18 |

| 1.65 |

16 |

| 3.05 |

11 |

| 25.4 |

0.89 |

20 |

| 1.25 |

18 |

| 1.65 |

16 |

| 2.11 |

14 |

| 2.41 |

13 |

| 3.05 |

11 |

| 28.58 |

1.65 |

16 |

| 31.75 |

1.65 |

16 |

| 2.11 |

14 |

| 3.05 |

11 |

| 34.93 |

0.89 |

20 |

| 38.1 |

1.25 |

18 |

| 1.65 |

16 |

| 2.11 |

14 |

| 3.05 |

11 |

| 44.45 |

0.89 |

20 |

| 1.65 |

16 |

| 2.11 |

14 |

| 47.63 |

1.65 |

16 |

| 50.8 |

1.25 |

18 |

| 1.65 |

16 |

| 2.11 |

14 |

| 3.05 |

11 |

| 53.98 |

1.65 |

16 |

| 57.15 |

1.65 |

16 |

| 2.11 |

14 |

| 3.05 |

11 |

| 63.5 |

1.65 |

16 |

| 2.11 |

14 |

| 3.05 |

11 |

| 69.85 |

1.65 |

16 |

| 76.2 |

1.25 |

18 |

| 1.65 |

16 |

| 2.11 |

14 |

| 3.05 |

11 |

| 82.55 |

1.65 |

16 |

| 3.05 |

11 |

| 88.9 |

1.65 |

16 |

| 101.6 |

1.65 |

16 |

| 2.11 |

14 |

| 108 |

3.05 |

11 |

| 114.3 |

1.65 |

16 |

| 127 |

1.65 |

16 |

| 2.11 |

14 |

| 3.05 |

11 |

| 4.78 |

|

| 152.4 |

1.65 |

16 |

| 2.11 |

14 |

| 3.05 |

11 |

| 203.2 |

3.05 |

11 |

Price list vary as per the Origin of material and manufacturing method, check price comparison of top 10 manufacturers of Seamless Carbon Steel Pipes

Difference between seamless pipe and erw pipe

| ERW Pipe |

Seamless Pipe |

| Manufactured by rolling metal and then welding |

Manufactured by extruding the metal |

| It has welded joint in its cross-section |

It does not have any welded joint |

| Its manufactured from Strip or Coil |

Its manufactured from solid round billets |

Maximum Allowed Stress of DIN EN 10220 seamless steel pipes

| NPS |

OD |

SCH |

WT |

Temp. (°C) |

Temp. (°C) |

Temp. (°C) |

| 343 |

371 |

204 |

260 |

399 |

427 |

| 1/2 |

21.3 |

STD |

40 |

2.77 |

29.3 |

28.5 |

34.5 |

32.6 |

22.4 |

18.6 |

|

3/4

|

26.7

|

STD |

40 |

2.87 |

23.8 |

23.1 |

28.1 |

26.5 |

18.2 |

15.1 |

| XS |

80 |

3.91 |

33.5 |

32.5 |

39.4 |

37.2 |

25.6 |

21.3 |

|

1

|

33.4

|

STD |

40 |

3.38 |

22.3 |

21.7 |

26.3 |

24.8 |

17.1 |

14.2 |

| XS |

80 |

4.55 |

30.9 |

30 |

36.3 |

34.3 |

23.6 |

19.6 |

|

1 1/4

|

42.2

|

STD |

40 |

3.56 |

18.4 |

17.8 |

21.6 |

20.4 |

14.1 |

11.7 |

| XS |

80 |

4.85 |

25.6 |

24.9 |

30.2 |

28.5 |

19.6 |

16.3 |

|

160 |

6.35 |

34.5 |

33.5 |

40.6 |

38.4 |

26.4 |

21.9 |

|

1 1/2

|

48.3

|

STD |

40 |

3.68 |

16.5 |

16 |

19.4 |

18.4 |

12.6 |

10.5 |

| XS |

80 |

5.08 |

23.3 |

22.6 |

27.4 |

25.9 |

17.8 |

14.8 |

|

160 |

7.14 |

33.8 |

32.8 |

39.8 |

37.6 |

25.9 |

21.5 |

|

2

|

60.3

|

STD |

40 |

3.91 |

13.9 |

13.5 |

16.4 |

15.5 |

10.7 |

8.9 |

| XS |

80 |

5.54 |

20.1 |

19.5 |

23.7 |

22.4 |

15.4 |

12.8 |

|

160 |

8.74 |

33.1 |

32.1 |

38.9 |

36.8 |

25.3 |

21 |

|

2 1/2

|

73

|

STD |

40 |

5.16 |

15.3 |

14.8 |

17.9 |

17 |

11.7 |

9.7 |

| XS |

80 |

7.01 |

21.1 |

20.5 |

24.8 |

23.5 |

16.1 |

13.4 |

|

160 |

9.53 |

29.5 |

28.6 |

34.7 |

32.8 |

22.5 |

18.7 |

|

3

|

88.9

|

STD |

40 |

5.49 |

13.2 |

12.8 |

15.6 |

14.7 |

10.1 |

8.4 |

| XS |

80 |

7.62 |

18.7 |

18.2 |

22 |

20.8 |

14.3 |

11.9 |

|

160 |

11.13 |

28.1 |

27.3 |

33.1 |

31.3 |

21.5 |

17.9 |

|

4

|

114.3

|

STD |

40 |

6.02 |

11.2 |

10.9 |

13.2 |

12.5 |

8.6 |

7.1 |

| XS |

80 |

8.56 |

16.2 |

15.7 |

19.1 |

18 |

12.4 |

10.3 |

|

120 |

11.13 |

21.4 |

20.8 |

25.2 |

23.8 |

16.4 |

13.6 |

|

160 |

13.49 |

26.4 |

25.6 |

31 |

29.3 |

20.2 |

16.8 |

| XXS |

|

17.12 |

34.3 |

33.3 |

40.4 |

38.2 |

26.2 |

21.8 |

|

5

|

141.3

|

STD |

40 |

6.55 |

9.8 |

9.5 |

11.6 |

10.9 |

7.5 |

6.2 |

| XS |

80 |

9.53 |

14.5 |

14.1 |

17.1 |

16.1 |

11.1 |

9.2 |

|

120 |

12.7 |

19.7 |

19.1 |

23.1 |

21.9 |

15 |

12.5 |

|

160 |

15.88 |

25 |

24.3 |

29.4 |

27.8 |

19.1 |

15.9 |

| XXS |

|

19.05 |

30.5 |

29.6 |

35.9 |

33.9 |

23.4 |

19.4 |

|

6

|

168.3

|

STD |

40 |

7.11 |

8.9 |

8.7 |

10.5 |

9.9 |

6.8 |

5.7 |

| XS |

80 |

10.97 |

14 |

13.6 |

16.5 |

15.6 |

10.7 |

8.9 |

|

120 |

14.27 |

18.5 |

17.9 |

21.8 |

20.6 |

14.1 |

11.7 |

| XXS |

160 |

18.26 |

24.1 |

23.4 |

28.3 |

26.8 |

18.4 |

15.3 |

Low Temp Seamless Pipe Charpy V-Notch Impact Tests

| Specimen Size |

*A |

*B |

| mm |

ft·lbf |

J |

ft·lbf |

J |

| 10 by 10 |

13 |

18 |

10 |

14 |

| 10 by 7.5 |

10 |

14 |

8 |

11 |

| 10 by 6.67 |

9 |

12 |

7 |

9 |

| 10 by 5 |

7 |

9 |

5 |

7 |

| 10 by 3.33 |

5 |

7 |

3 |

4 |

| 10 by 2.5 |

4 |

5 |

3 |

4 |

Hot Forming and Heat Treatment of CS ERW and Seamless pipe

| Heat treatment |

Hot forming |

| Normalizing 1) |

Stress-relieving anneal 2) |

Type of cooling |

Temperature °C |

Type of cooling |

| 890 – 950 °C |

600 – 650 °C |

Air |

1100 – 950 |

Air |

List of machinery to produce seamless pipe

- Piercing Mill

- Slight-stretch Reducing Mill

- Rotating Heat Furnace

- Cooling Bed

- Hot Rolling Mill

- Tube Cutter

List of machinery to produce welded pipe

- Decoiler + Hydraulic Feeding table

- Leveling unit

- Hydraulic Puncher Unit

- Roll Forming Machine

- Hydraulic Pump Station for mail machine

- Electricity control cabinet

- Cutting precision

Testing for Seam pipe and ERW Pipe

- Chemical composition analysis

- Surface quality inspection

- Ultrasonic testing

- Eddy current flaw detection

- Magnetic particle testing

- Penetration inspection

- Tensile test

- Hardness test

- Hydraulic test

Component Parts

Powder Coating Machine,Tinplate Powder Coating Machine,Automatic Aerosol Can Leaking Tester,Metal Packaging Manufacturing Equipment

Zhoushan Longwen Machinery Technology Co., Ltd. , https://www.longwenmachinery.com